|

|

How,

whereas in the case of friction wheels, which are incapable of

transmitting large forces and which, forcibly lead to a certain slippage,

in the case of gears, the liason, obtained by obstacles, makes for a true

transfer of power and can transmit considerable tork

values.

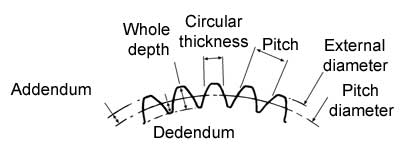

The elements making up a toothed wheel which correspond to a

friction wheel are called the pitch elements: pitch circle, cylindrical

pitch, pitch circle diameter (PCD). These elements are very difficult

to measure on a gear.

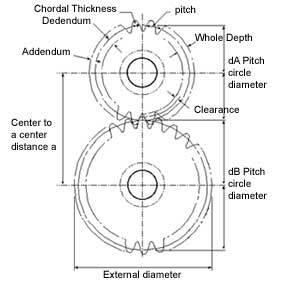

The coupling of

two wheels working together is known as a gear. When the two wheels are of

different diameters, the smaller of the two is known as a pinion, the

larger - the gear.

The drive

wheel governs the movement of the driven wheel.

A rack is

considered to be a wheel of infinite diameter (it's pitch surface is a

plane).

The

cylindrical pitch of a gear is an imaginary cylinder whose surface

form is found by meshing gears so that the surfaces actually touch each

other (in other words - it is as if you are using two friction wheels of

the same diameter). A straight section through this cylinder will give the

pitch circle, which has a diameter d(PCD).

The external

diameter is the diameter measured from the highest point on the

teeth.

The base circle

diameter is the diameter when measured from the root of the

teeth.

The face is the

portion of the surface of a tooth between the head and

root.

The Circular

Tooth Thickness is the length of the arc between the two faces of a tooth.

Taken from the PCD.

The profile is a

section through the face of the tooth. The form of this profile is known

as an INVOLUTE

CURVE.

The pitch

is the length of the arc, measured on the pitch circle, between similar

points on two consecutive teeth. It is equal to the product of ![]() and the

module.

and the

module.

The module

is used as a basis for all calculations of tooth dimension. This parameter

may be found easily by a mathematical formula..

In order for two

wheels to mesh they must have the same module (the same size of

tooth). Two gears of different modules will be

incompatible.

The dimensions of

a spur gear are defined by the number of teeth and it's module. All

other dimensions are linked to these two by The following

formulas:

|

STANDARD TOOTH |

Sym-bols | Formulas | Unit |

| Module | m | p |

mm | |

| Pitch | p | m x |

mm | |

| PCD | d | Z x m | mm | |

| number of teeth | Z | d |

||

| External diameter | D | (Z + 2) x m | mm | |

| Addendum | ha | m | mm | |

| Dedendum for mod. 0,25 to 1,25 | hf | 1,40 x m | mm | |

| Dedendum

for 1,5 to 8 |

hf | 1,25 x m | mm | |

| Whole depth

for mod 0,25 ?nbsp;1,25 |

h | 2,40 x m | mm | |

| Whole depth

for mod 1,5 ?nbsp;8 |

h | 2,25 x m | mm | |

| Circular thickness | e | mm |

Consult tooth size for gears of module 0,20 to 6.

| Centre to centre | 2 |

The centre to centre distance tolerance is 0/+0.05 |

| Speed ratios | W1 = Z2 W2 = Z1 |

W1 = Input speed W2 = Output speed Z1 = Number of teeth on drive wheel Z2 = Number of teeth on driven wheel |

To assure continuous meshing, One couple of teeth must mesh before the previous pair seperates. In the case where there are a small number of teeth on a gear, a correction will be necessary to avoid interference between consecutive pairs of teeth.

Correction of teeth for gears of 8 to 17

teeth..

A tooth

correction may be carried out on the gear to avoid interference which

may occur at the base of the teeth. ATTENTION. This procedure will

modify the PCD of the wheel, thus the centre to centre

distance.

Corrected teeth |

Symbols | Formulas | Unit |

| Corrected PCD | dc | m (Z + 1) | mm |

| Corrected external diameter | Dc | m (Z + 3) | mm |

Advantages, inconveniences and advice.

- Possibility of axial displacement,

- No

axial forces,

- Reduction ratios of 2:1 to 40:1

- The

simplest of gear systems

- Gears

of the same module are interchangeable.

|

|

|

The pitch circumference is : |

Pitch circumference = |

Also |

Pitch circumference = Number of teeth x Pitch |

Therefore : |

Number of teeth Z x Pitch (P) = |

Therefore : |

|

Where P = Pitch, d = PCD and Z = Number of teeth | |

| By definition, the resultant is known as the Module (m). It can be shown that : | |

| Therefore the basic formuli for gears may be found | |

d = m

Z | |

p =

| |

From a

geometric point of view, the module can be found on a tooth. It is the

distance, in mm, between the Pitch arc and the External arc. For example,

for module =2, there will be 2mm between the Pitch and External circles.

Returning to the diameters, to find the external diameter it is necessary

to add 2 x module to the PCD.

| Therefore one finds : | d(ext) =

m Z + 2m |

d(ext) =

m (Z+2) | |

What is the shape of an involute curve?

This

shape is defined by the trajectory of a point situated on a spur which

will roll, without slipping, over a circle. This form has many

advantages..

- There

is a large tolerance in the distances between the gears before the

operation of the system is affected.

- One

single tool per module, allows for the machining of all sizes of wheel,

how many teeth they have.

- The

wear on the mating surfaces of the gears is much more evenly spread than

on other profiles.

- Vibration levels are lower than other profiles.

See also