|

|

|

|  |  |  |

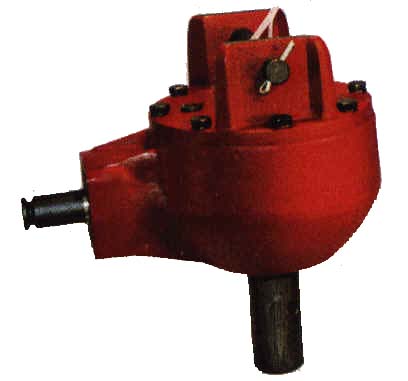

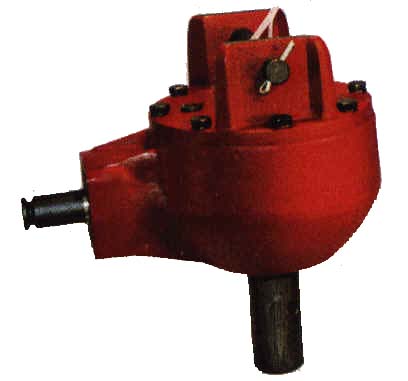

WORM GEAR REDUCERInch DimensionMetric DimensionAluminum Series

| CYCLOIDAL REDUCER | HELICAL GEAR REDUCER | COMBINATION OF REDUCER AND VARIATORS | SPECIAL REDUCER |

|

|

Stepless Variable MACHINERY& Reducer

|

|

|

|  |  |  |

WORM GEAR REDUCERInch DimensionMetric DimensionAluminum Series

| CYCLOIDAL REDUCER | HELICAL GEAR REDUCER | COMBINATION OF REDUCER AND VARIATORS | SPECIAL REDUCER |

Press here for conveyors and rollers

Products:

Helical shaft mount gearboxes

Helical Shaft Mount Reducers & Gearmotors

hollow shafts

In-Line Helical Reducer

PV Series planetary gearboxes

Gear, Gear & Engineering, gearmotor, gearmotors, gear motor, gear motors,

reducer, reducers, gear reducer, gear motor reducer, dc motor, dc motors, pmdc

motor, pmdc motors, iec motor, iec motors, ac gear motor, dc gear motor,

parallel shaft gear motor, parallel shaft gearmotor, right angle gear motor,

right angle gearmotor, gearbox, gearhead, gear head, gear case, concentric,

planetary

AC Parallel Shaft Gearmotors

AC Right Angle Gearmotors

DC Parallel Shaft Gearmotors

DC Right Angle Gearmotors

AC Motors

DC Motors

Gear Reducers

AC Accessories

DC Accessories

Gear, gears, bearings, speed reducers, worm gear speed reducers, motors,

couplings, clutches, drives, MACHINERY, mechanical, controllers,

pneumatics, helical, electrical, inverters, washdown, brakes, worm drives, 700

Series, 600 Series, 200 Series, 800 Series, drives, DC, AC, motor, bevel,

Colfax, Bost-Kleen, BostSpec, packaging machinery, bronze, Centric, gear drive,

clutches, Colfax PT CO., LTD., controllers, conveyor components, electrical,

enclosed gear drives, gear, gear box,inverter, material handling equipment,

micro-controllers, miter and bevel gears, open gearing, planetary motor

multiplier, spiral bevel, speed reducer, universal joints, worm drives, Cad

drawings, food processing, design engineers

gearbox, gear box, gear and box, gearhead, speed reducer, gear reducer, gear

drive, planetary gear, gear box metal, box fleetwood gear, gear box steering, 3

gear box metal solid, right angle head, angle gear box right, gear box trailer

Gearboxes

Shaft Mount Gearboxes || Helical Gear Boxes || Planetary Gear Boxes || || Worm

Gear Boxes || Bevel Gear Boxes || Reduction Gear Boxes || Custom Gear Boxes ||

Shaft Mounted Taper Clamp Units || Shaft Mounted Screw Conveyor Units ||

Accessories

Industrial Gears :

Worm Gears || Bevel Gears || Planetary Gears || Helical Gears || Hardened Ground

Gears || MACHINERY Gears

Other Products : Timing Pulleys || Slewing Rings || Sprockets

Right Angle gearbox | Worm Gear Box | Industrial gear boxes | Custom Gear Box |

Worm Shaft and Worm Gears drives | Rack and Pinion Gears | Bevel Gears | Spur

gears | Helical gears | Double Helical gears | Roller Chain Sprockets | Helical

and Bevel Helical Gear Box

Automotive Gears Bevel Gears Gear Assemblies Gear Reducer Gear Shafts

Gearbox Girth Gears Ground Gears Helical Gears Industrial Gears

Planetary Gears Plastic Gears Precision Gears Sprockets Spur Gears Worm

Gears

introduce

Speed reducers, also called a gearboxes and gearheads, as well as gear reducers

etc., consist of a set of gears, shafts and bearings that are factory mounted in

an enclosed lubricated housing. Speed reducers are available in a broad range of

sizes, capacities and speed ratios. Their job is to convert the input provided

by a prime mover (usually an electric motor) into an output of lower RPM and

correspondingly higher torque.

Important performance specifications to consider when searching for gearboxes

and gearheads include gear ratio, output torque, maximum input , and

maximum input speed. Ratios are generally specified at X: 1, where X is an

integer. Therefore a ratio of 5:1 is specified as 5. A 5:1 ratio means that a

motor input of 1750 RPM is converted to 350 RPM. A reducer's input HP rating

represents the maximum prime mover size the reducer is designed to handle.

Exceeding the maximum input speed can result in oil "churning", which is

detrimental to the life of the speed reducer.

Gearing arrangements for gearboxes and gearheads include spur, helical,

planetary, harmonic, worm, bevel, and cycloidal. Spur gears are gears with teeth

that are straight and parallel to the axis of rotation. They are good for

parallel shafts. Helical gears are gears with teeth that spiral around the gear.

They are similar to spur gears but with greater time of contact and quieter.

Planetary gears get their name from a resemblance to a solar system. Planetary

reducers can be designed with gear sets or a set of planetary cones. In

planetary gear reducers, planet gears revolve around a sun gear. The input shaft

rotates the sun gear. Each of the planet gears simultaneously applies a torque

to the rotating planet member that then applies a torque to the output shaft

(back side). Planetary cone reducers operate on a similar principle, utilizing

an input disc, control ring, and planetary cone train instead of a gear

set. Harmonic gears utilize a nested gear within a circular spline, the inside

one being flexible and containing two fewer teeth. Each turn of the inside moves

the flexible gear anti-clockwise on the Circular Spline. A worm gear is a

threaded input shaft meshed with a worm gear that is mounted to the output

shaft. These are usually used for right angles. Bevel gears are gears that

shafts lie perpendicular to each other, therefore utilized mainly in right-angle

applications. Miter gears are bevel gears with a 1:1 ratio. They are not used

for speed reduction. Cycloid reducers use rolling elements (such as a cam

follower) and a multilobe cam to transmit torque and provide speed reduction.

Cycloidal reducers can provide high reduction ratios with low backlash, high

accuracy, and high stiffness. The load-sharing feature of cycloidal reducers

also allows it to withstand high shock loads.

A speed reducer is termed a gearhead if it is entirely and directly mounted onto

a motor, not just the shaft. Therefore, other speed reducers (gearboxes) are

typically coupled with the shaft and then base-mounted. The coupling of the

shaft from the prime mover to the input shaft of the speed reducer can be

accomplished in a few different ways. If the two shafts are coupled

shaft-to-shaft directly, a coupling is required. If they are not coupled

shaft-to-shaft, the speed reducer generally has a "quill-style" or hollow shaft

for the prime mover shaft to mount into. The coupling is accomplished with a

clamping pinion gear or adapter plate. Specific NEMA face adapters (coupling

type) are also manufactured to eliminate sizing concerns between motor and

gearbox.

Input and output configurations for gearboxes and gearheads include hollow

shaft, hollow shaft, or coupling or bushing. A single input shaft can drive

multiple output shafts. The output shafts are usually parallel and in-line.

How, some unique configurations exist that allow for offset shafts to be

driven at different speeds. Some gearboxes and gearheads can be supplied with a

reaction arm. A reaction arm prevents the reducer housing from rotating when

there is no base mounts or flanges. Shaft alignment can be parallel in-line,

parallel offset, right angle, and non-perpendicular angled shafts. Shafts can be

aligned vertically as well. In order for a shaft to be orientated in a vertical

position, considerations need to be made regarding lubrication.